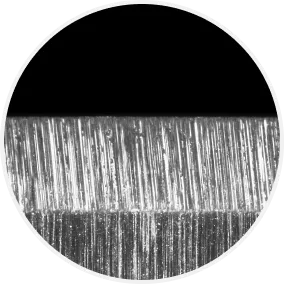

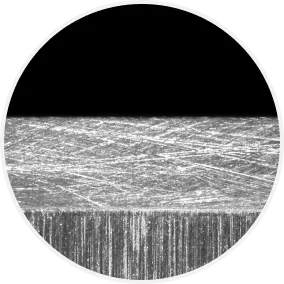

The reference taken for comparison with the microscope is a standard high-end knife after leaving the factory.

It corresponds to the sharpening result after using the standard grain diamond grinding wheel and the ceramic polishing wheel.

With the HORL® standard grain diamond grinding disc, you can obtain a high-quality sharpening result in a short time and without using water. The synthetic diamonds we use are ideal for sharpening any type of steel, regardless of the degree of hardness, and guarantee effective and precise results. In addition, they offer an edge finish comparable to that of a high-quality German knife fresh from the factory. If the diamond grinding wheel is used correctly, it does not need to be replaced.

After using the standard grit HORL® diamond grinding disc, the ceramic disc allows for a much finer sharpening. The serrations it presents guarantee a smooth edge and also eliminate excess material remains.

The 20° sharpening angle allows you to sharpen knives quickly and obtain a stable edge. The knives stay sharp for a long time and can be used daily in the kitchen to make different cuts. Even when used on many hunting knives and folding knives, it provides a stable edge and excellent sharpness for everyday use.

With the 15° sharpening angle, even the finest blades, such as Damascus steel or high-quality carbon steel, can achieve exquisite sharpness. These blades can be sharpened to a very fine finish while maintaining their stability.

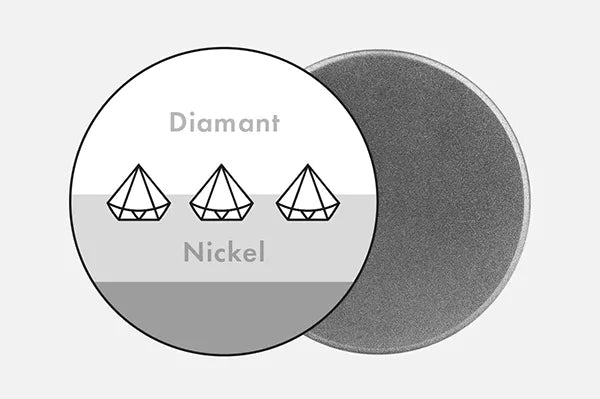

Synthetic diamonds are considered some of the most durable and effective abrasive discs on the market. Monocrystalline diamonds are harder than any knife steel. The diamonds in the standard grit HORL® Diamond Grinding Wheel are set using an electroplating process in which they are immersed 55% in a nickel bath. The rough surface is smoothed with the first movements until it reaches a smooth state, which remains in this shape.

The combination of strong neodymium magnets and the thin HORL® S-Pad silicone membrane allows the knife to be attached to the holder. Thanks to its non-slip function, even the smallest blades can be sharpened precisely and consistently to the desired height.

DELIVERY VOLUME

HORL® 2 walnut

HORL® 2 walnut sharpening stand

Original HORL® 2 packaging

QUESTIONS? ANSWERS.

When sharpening knives with particularly high blades, the cutting edge will extend beyond the sharpening wheel. In this case, it is recommended to place the sharpening roller on a non-slip cutting board as a chock, so that the cutting edge is at the same height as the radius of the sharpening disc. VIDEO

If dust accumulates on the diamond and/or ceramic disc after a few sharpening movements, it can be easily removed with an eraser. If necessary, the diamond grinding disc can be unscrewed and cleaned with a brush, hot water and a little dish soap. If the surface is not very dirty, a couple of passes with an eraser would be enough. VIDEO

Hold the HORL® sharpener firmly with one hand. With the other, unscrew the sharpening disc that is already assembled. Instead, screw on the desired disc. Note: The sharpening discs can be replaced on the HORL2®, HORL2 Pro® sharpener models and the first generation of HORL® sharpeners. VIDEO

The time it takes to sharpen a knife for the first time to restore its edge can vary depending on the condition of the blade and the quality of the steel. The amount of time to be spent will depend on factors such as the quality of the steel and the maintenance that has been given to it in the past. On average, it takes about five minutes, as the knife must first learn the chosen angle (15° or 20°). If a constant sharpening angle is maintained, a few sharpening passes will be enough in the future to maintain the sharpness. VIDEO

In knives that have until now been sharpened freehand, the angle of the edge usually changes after each sharpening. Therefore, it is impossible to determine the exact angle of the blade. In that case, it is important to sharpen the knife once with the HORL® sharpener and magnetic holder to obtain a constant sharpening angle that can be reproduced with each sharpening session. VIDEO