Montefeltro Shotgun Crio Center

- In stock, ready to ship

- Inventory on the way

Extremely versatile semi-automatic, precisely tuned for stability and ease of handling.

It is prepared to shoot with a wide range of cartridges.

The carbon fiber band is non-deformable in the heat of the gun, thanks to its characteristics of resistance and elasticity.

Mechanical guarantee of 5 years.

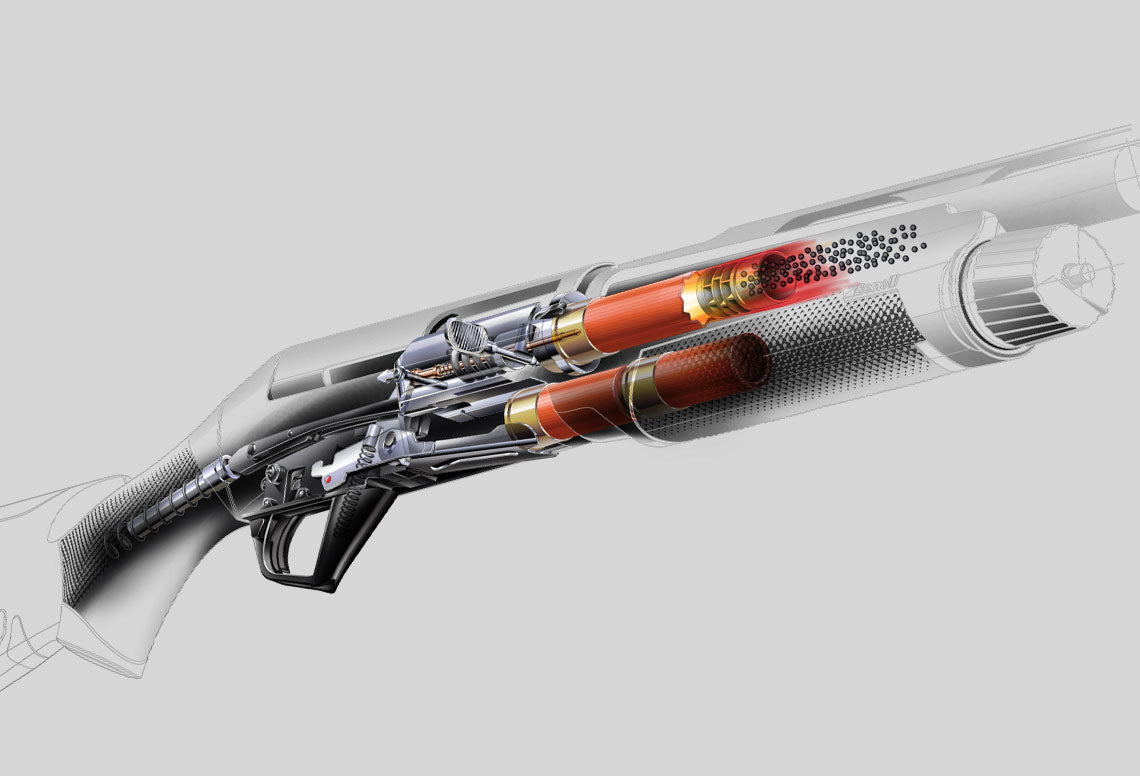

INERTIA DRIVEN SYSTEM

Made up of three components: the shutter, the closing head and the free spring. While the shutter is positioned to fire, the turning bolt moves along a profiled guide to occupy the closing head. When the trigger is pulled, all shotgun components except the shutter move rearward. Meanwhile, the inertial spring is compressed between the shutter head and the shutter body. In this way the casing moves from the chamber to the explosion chamber. The heavy inertial spring pushes the shutter group back, extracting the fired cartridge. When the empty cartridge comes out, the energy is used to reset the hammer, advancing the cartridge to the correct position, inserting a new cartridge into the chamber. This ensures smooth operation.

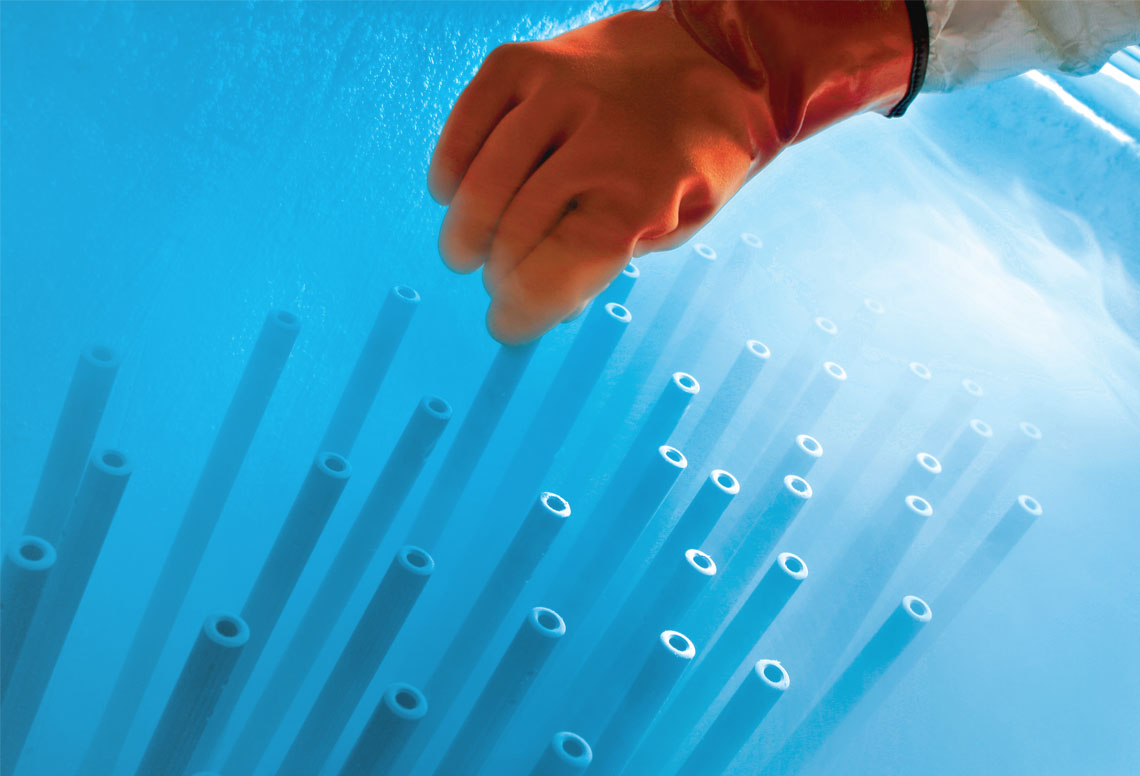

CRYO SYSTEM

Cryogenic treatment applied to the barrel and choke of a light weapon to maximize its ballistic performance. The Benelli Crio System treatment consists of gradually cooling the steel until it reaches temperatures of -100º C. The first element to which the Crio System has been applied is the CRIOBARREL barrel. With this cryogenic treatment, the consequences of heat and fiction are minimal, thus the barrel expands uniformly at the moment of firing. Likewise, this treatment lengthens the life of the barrel, since it is more resistant to wear and The cryogenic treatment also has positive effects on the useful life of the barrel, since it is more resistant to wear and does not suffer the effects of combustion residues.

Also applies to chokes, CRIOCHOKES . They have a special elongated shape with a gradual widening. In this way the pellets do not accumulate and their deformation is reduced. With the Crio System, the trails of shot are much denser with full roses in the central and peripheral parts.

- Gauge: 12

- Chamber: 76

- Barrel: 66 / 71

- Chokes: 5 chokes

- Band: Ventilated carbon

- cryogenic cannon.

- Weight: 3.15Kg

- It comes in the original Benelli briefcase.